OTS PROTECTIVE JACKET

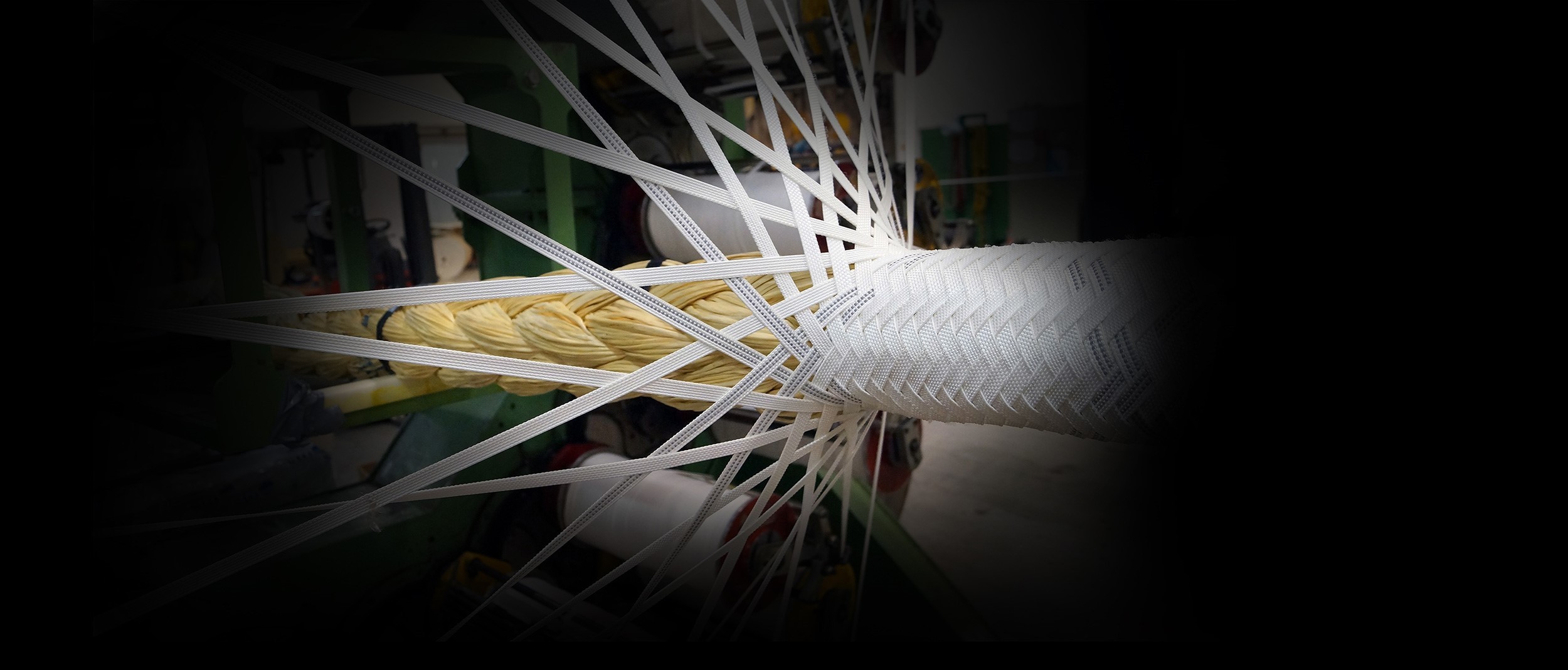

The patented chafe gear - OTS Protective jacket™ - offers excellent protection against external abrasion and increases rope lifetime with up to five times. The "no-rupture" construction combined with the worlds most abrasion resistant synthetic fibers, makes this the best cut -and abrasion resistant cover for your ropes. The jacket is mechanically braided onto the rope for a firm and solid finish.

Download productsheet (pdf)

OTS Protective jacket™ is braided in the following combinations:

- Soft eyes

- Soft eyes and required length (for instance over the splices)

- Exposed area on the rope

- Entire rope length

OTS Protective Jacket™

- Made with HMPE or polyester fiber.

- The OTS Protective Jacket™ comes out as a clear winner in comparative testing of abrasion and cut resistance.

- Excellent protection against wear and tear.

- Patented technology

Advantages

- Increases service life.

- Can be braided onto entire rope or exposed areas.

- Prevents rope from twisting.

- Protects rope from external abrasion.

- Reduced size of mooring line.

- Reflective material can be woven into jacket band for better visibility.

- Jacket band can be delivered in any colour.

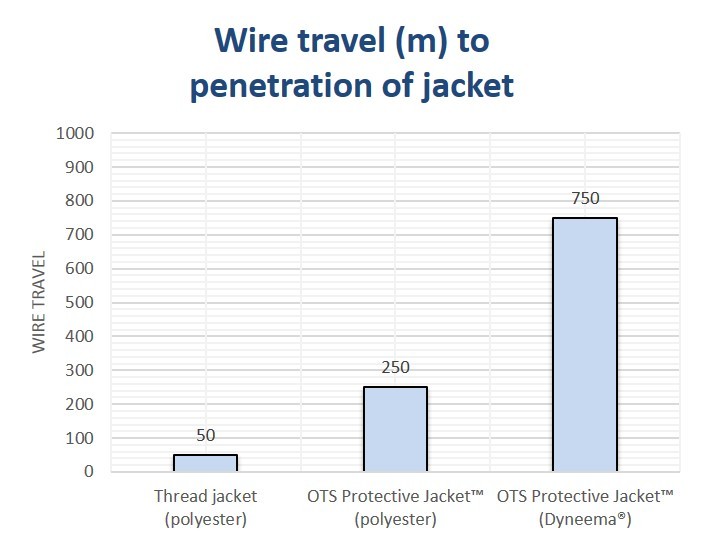

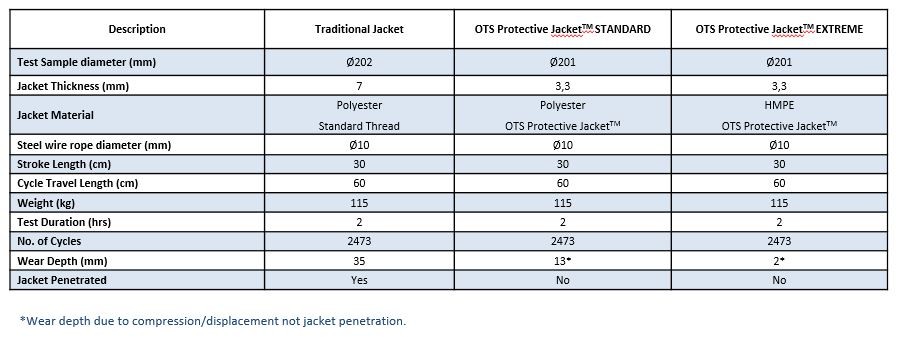

Proof of Performance - OTS Protective Jacket™ Cut Test

Test No.1

The sample of fiber rope was mounted in a steel frame. The fiber rope was held in place by two cargo straps. A steel wire was running perpendicular to the axis of the fiber rope connecting a weight to a pneumatic cylinder. Through the reciprocating movement of the cylinder, abrasive wear was inflicted to the fiber rope. A water nozzle sprayed the contact area providing cooling to the rope, hence, reducing frictional heating. The stroke length was set to 30cm, giving each cycle a total traveling distance of 60cm. Number of cycles was counted during the test. Each cycle corresponded to approximately 60cm of travel for the steel wire. Test time was set to 120 minutes (the test setup can be set to last for a specific amount of time or to a specific amount of cycles has been carried out).

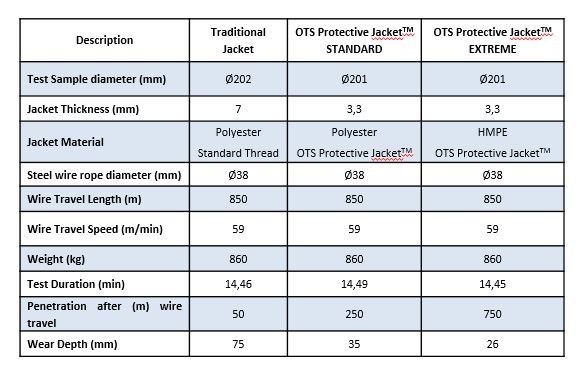

Test No. 2

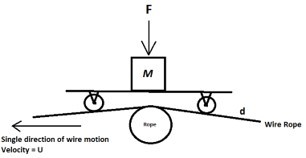

The sample of fiber rope was mounted in a steel frame. The fiber rope was held in place by two cargo straps. A steel wire was running perpendicular to the axis of the fiber rope, the wire rope had one single direction of motion at a constant velocity. A weight was placed onto the wire rope to create a constant contact force between the wire rope and the fiber rope sample. Abrasive wear was inflicted to the fiber rope. A water nozzle sprayed the contact area providing cooling to the rope, hence, reducing frictional heating. The wire travel length was 850m.

Performance

- OTS Protective Jacket™ is performing even better than expected.

- Rope size is reduced due to thinner jacket bands.

- Partners within the Mooring industry is introducing new jacket standards to the market; Standard and Extreme.

- If more abrasion resistance is needed, thicker bands can be engineered for specific projects.

- The excellent properties of the OTS Protective Jacket™ can make it the industry standard for all mooring lines.