Mooring Ropes

We deliver mooring ropes for your net cages.

Contact us for a thoruogh walkthrough and recommendations.

Dextron®12 Plus is a torque-free, 12-strand braided rope with maximum strength-to-weight ratio and size-for-size has the same strength as steel. Dextron®12 Plus is made with Dyneema® SK78 and is an excellent wire rope replacement with extremely low stretch, superior flex fatigue and wear resistance.

Dextron®12 Plus is Type-Approved by DNV. Download certificate

|

Applications

|

Special Properties

|

Characteristics:

| Material | Dyneema®SK78 |

| Colour of rope | Yellow |

| Elastic elongation | 0,44% at 10% of breaking load 0,62% at 20% of breaking load 0,79% at 30% of breaking load |

| Water absorption | None |

| Abrasion resistance | Very good |

| Fatigue resistance | Excellent |

| UV exposure | Very good |

| Chemical resistance | Excellent |

| Melting range | 144-152 ºC |

| Max work temp. | 65ºC |

| Specific density | 0,98 (floating) |

The 12-strand polyester rope made by OTS is a torque-free rope suitable for towing pennants, towing lines, and mooring lines. Made with High Tenacity Polyester fiber (HT Polyester) the 12-strand polyester rope offer high-strength and good abrasion resistance.

|

APPLICATIONS

|

SPECIAL PROPERTIES

|

Characteristics:

| Material | Polyester |

| Colour of rope | Grey (or yellow with black and blue tracer) |

| Elastic elongation | 4,0% at 20% of breaking load 7,5% at 40% of breaking load 10,5% at 60% of breaking load |

| Water absorption | <0,5% |

| Abrasion resistance | Very good |

| Fatigue resistance | Good |

| UV exposure | Good |

| Chemical resistance | Good |

| Melting range | 254-260 ºC |

| Max work temp. | 90ºC |

| Specific density | 1,40 (non-floating) |

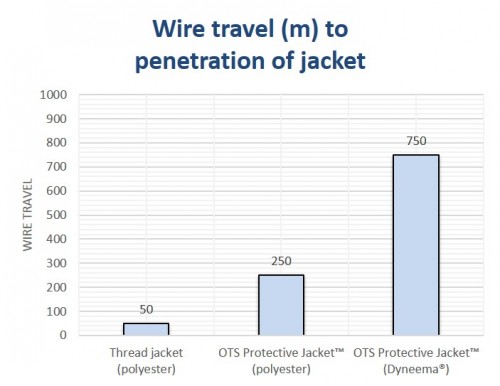

The patented chafe gear - OTS Protective jacket™ - offers excellent protection against external abrasion and increases rope lifetime with up to five times. The "no-rupture" construction combined with the worlds most abrasion resistant synthetic fibers, makes this the best cut -and abrasion resistant cover for your ropes. The jacket is mechanically braided onto the rope for a firm and solid finish.

OTS Protective jacket™ is braided in the following combinations:

- Soft eyes

- Soft eyes and required length (for instance over the splices)

- Exposed area on the rope

- Entire rope length

|

OTS Protective Jacket™

|

Advantages

|

OTS Chafe Gear™ has been used by operators in the marine and oil & gas industry for over a decade, and lately it has also become more common in the fishing industry. The durable construction with its high abrasion resistance is demonstrated daily.

There are two types of OTS Chafe Gear™; a sleeve without axial velcro which is used prior to and during splicing of the rope, and a sleeve with super strong velcro which enable assembling of the sleeve anywhere on the rope without re-splicing. The chafe gear is also fitted on chains and other hardware to protect sorroundings from chafing against the hardware.

Options

- Ears for fastening of seizing rope

- Velcro locking straps in the ends and/or mid-sections of the sleeve

- Loocking hoops

OTS Chafe Gear™ with super strong velcro

OTS Chafe Gear™ with super strong velcro

OTS Chafe Gear™ with locking hoops

OTS Chafe Gear™ with locking hoops

OTS Chafe Gear™ on chains

OTS Chafe Gear™ on chains